Equipment Case Studies

-

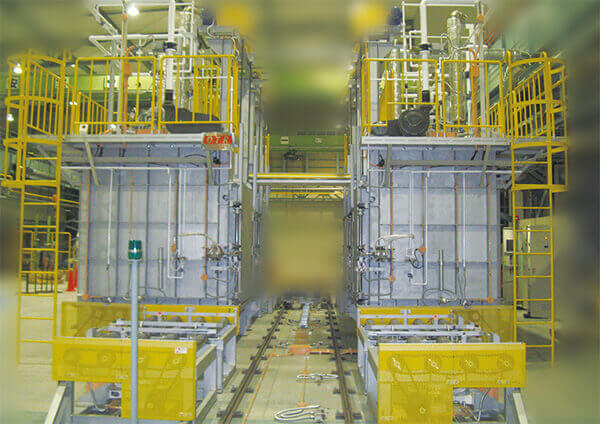

Walking beam type heating furnace for rolling

Basic specifications

Furnace temperature 1,000℃ Materials treated Copper: 3/7 copper, 4/6 copper Fuel used LNG city gas 13A Transport device Stock table Carry-in conveyor and lifter Side roller for inserting material into the furnace Walking beam for transferring material into the furnace Extraction rollers for removing material from the furnace Extraction lifter RT roller hearth continuous annealing furnaces

Basic specifications

Maximum operating temperature 650℃ Materials treated Copper and copper alloys Throughput 5,500 kg/hr. (standard) Fuel used Butane gas Maximum combustion (amount) 5,110 MJ/h (122x104 kcal/h) DX gas generation (amount) 140N㎥/h Transport device In-side V-type conveyor and reverser In-side traverser Out-side traverser, coil car Out-side V-type conveyor and reverser of Roller hearth system Brass wire rod coil annealing furnace of batch system

Basic specifications

Furnace operating temperature 450℃ ~ 550℃ Maximum operating temperature 650℃ Materials treated Copper and copper alloys Maximum amount processed 1.5t / charge Purpose of the processing operation softening and annealing Equipment configuration Annealing furnace x 4, Standby table x 4, Cooling table x 4, traverser table in front of furnace x 1 Roller hearth type aluminum bar heat treatment furnace of RT system

Basic specifications

Furnace operating temperature 120℃ ~ 410℃ Materials treated Aluminum bar / aluminum material coil Maximum operating temperature 600℃ Maximum load 2,500 kg / charge Purpose of the processing operation Tempering / Annealing Maximum combustion (amount) 880 MJ/h (21×104 kcal/h) Equipment configuration Heat-treatment furnace, front and rear transfer equipment Heat treatment furnace, back and forth transfer device

Basic specifications

Furnace operating temperature Melting furnace:520℃(MAX600℃) Yielding water tank:40℃~60℃ Time effect furnace:200℃(MAX350℃) Materials treated Aluminum alloy castings Maximum amount processed 740 kg / charge Equipment configuration Input table Melting furnace Quenching equipment (water tank, elevator) Aging furnace Output table Handler type batch processing non-oxidizing annealing furnaces

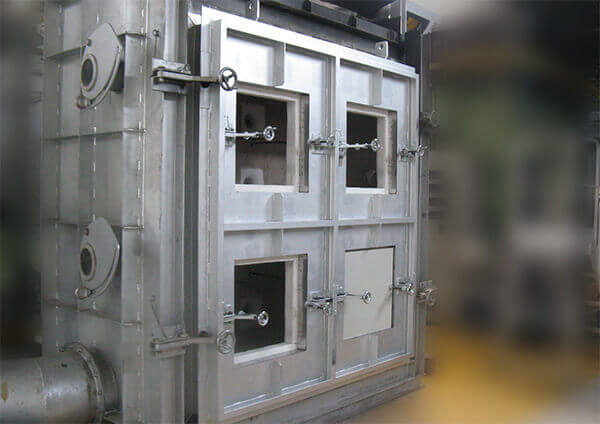

Basic specifications

Furnace operating temperature 160℃ ~ 650℃ Maximum operating temperature 700℃ Maximum amount processed 2.0t / charge Purpose of the processing operation Non-oxidation tempering (softening annealing, spheroidizing annealing) Atmosphere within the furnace N2 gas Maximum combustion (amount) 838 MJ/h(200,000 kcal/h) Equipment configuration Non-oxidizing annealing furnace, table in front of furnace Mesh belt type continuous annealing furnace

Basic specifications

Furnace operating temperature 400℃ ~ 600℃ Maximum operating temperature 650℃ Materials treated Round bars, etc. (S35C to S45C, SCM435, 440) Purpose of the processing operation Tempering / annealing Bandwidth Time 90 ~ 120min Maximum combustion volume 1,257 MJ/h(300,000 kcal/h) 300t ladle preheating device

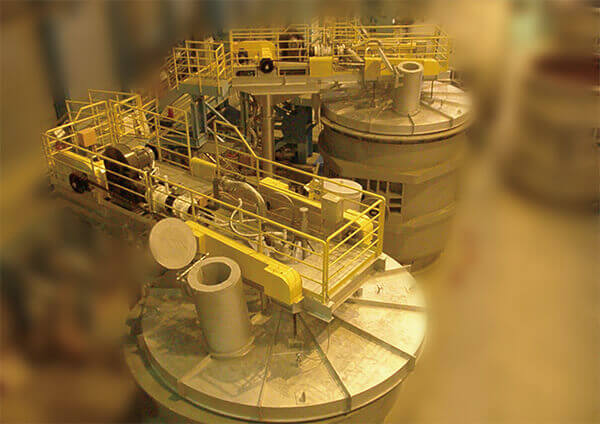

Basic specifications

Ladle capacity 300 t Maximum combustion volume 12,570MJ/h (3,000,000 kcal/h) Fuel used Propane Preheating lid drive system Self-supporting rotary pillar type Others With oxygen load combustion function

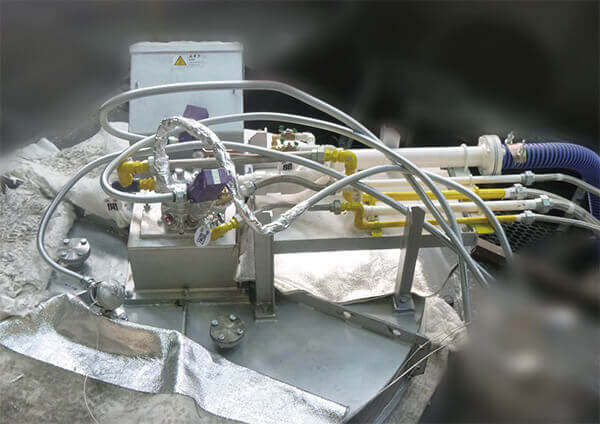

Basic specifications

Ladle capacity 3.4 ~ 15.8 ㎥ Combustion capacity 4,190 MJ/h (1,000,000 kcal/h) Fuel used COG * Pilot burner: LPG Atmosphere temperature in ladle 700℃ Preheating lid drive system Self-supporting rotary pillar type Gas torch for drying ladle

Basic specifications

Inner pot capacity 1.0 ㎥ Combustion Capacity 608 MJ/h (145,000 kcal/h) Use of fuel butane air gas Atmosphere temperature in the pot 700℃ Electricity-heated hot air circulating pot drying furnace

Basic specifications

Processing details Drying of ladle for molten aluminum Furnace operating temperature 260℃ Maximum operating temperature 300℃ Electric heater capacity 75kW Maximum processing capacity 1,000kg/unit × 1 unit Others Material loading method: manual operation by forklift. Panel test furnace

Basic specifications

Processing details For fire resistance testing of test panels Combustion capacity 3,545 MJ/h(846,400 kcal/h) Maximum operating temperature 1,100℃ Others With deodorizer (Temperature) 800°C (Combustion capacity) 2,685 MJ/h (640,900 kcal/h) Electricity-heated die preheating furnace

Basic specifications

Processing details Dice preheating Furnace operating temperature 450 ~ 550℃ Maximum operating temperature 600℃ Others manual take out